CRP Subsea was awarded a contract by eni to provide a microseismic cable riser system on five shallow water platforms located in the Adriatic Sea off the coast of Ravenna, Italy.

The retrofit cable riser system will allow a 16mm diameter microseismic monitoring cable to be installed at each platform. The monitoring cable will rise from the subsea frame and be securely attached to the jacket leg, in order to be connected to a junction box located on the deck. The monitoring cable will be protected from environmental actions and marine growth from the seabed to above the splash zone.

Ben Stubbens, Team Sales Manager at CRP Subsea states:

“We are delighted to be awarded this contract to supply microseismic cable riser systems for eni. By collaborating with them and understanding their specific requirements, we have used our engineering expertise in piggyback clamps to create a bespoke solution. It’s fantastic to be part of this innovative project that aims to have a contribution to achieving zero net emissions by 2050.”

Production of the retrofit cable riser system has taken place in CRP Subsea’s state-of-the-art manufacturing facility in the North West of England, with installation happening later this year.

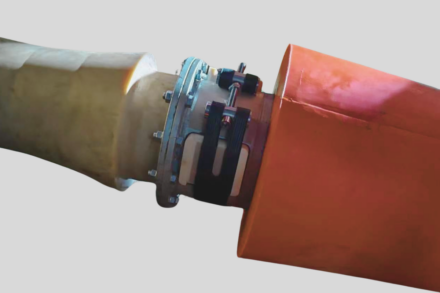

The microseismic cable riser system will consist of a Polyethylene (PE) riser system, retrofitted to the selected jacket leg on each platform. The riser system will comprise of 5 metre sections of PE pipe fastened together with Polyurethane (PU) connectors to form an I-tube, at the end of the I-tube there will be a PU bellmouth. PU clamps will be used to secure the PE pipe to the jacket leg, secured in place with aramid fibre straps and Super Duplex tensioning assembly.

Find out more about our piggyback clamp system here.