Why AIS?

Proven technology. Delivered worldwide.

AIS has a powerful track record of developing innovative solutions that provide reliable battery protection in critical safety scenarios.

Wide range of solutions

AIS offers various battery protection solutions, including innovative materials to protect a range of batteries from single cell to full pack level, as well as an in-house test facility.

Speed and agility

All AIS solutions are designed, tested and manufactured in-house, reducing lead times and reflecting the fast pace of the battery protection sector.

Bespoke engineering

With a problem-solving ethos, we work closely with our customers to deliver the tailored solutions that meet their precise requirements.

Battery protection

Solutions (A-Z)

Abuse and homologation

A full suite of battery abuse testing to assess the safety and durability of batteries under extreme conditions.

Battery assessment and consultancy services

Optimise and better understand the performance, safety, and longevity of your battery systems with our rigorous testing capabilities.

Battery testing service

Destructive and non-destructive testing of Li-ion cells, modules, and high-voltage packs.

Cell dividers

Enhance the safety of battery packs by providing separation between individual cells.

Climatic and life testing

Advanced testing facilities and cutting-edge equipment to simulate a wide range of climatic conditions.

Fireproof coatings

Coatings that protect lightweight and thin components from fire and thermal runaway.

Rebound protection

Materials that fill battery module enclosures, effectively controlling and containing the flow of fire or hot gasses.

Thermal barrier materials

Thin, lightweight materials to protect against extreme events including a fire or thermal runaway

Battery protection

Applications (A-Z)

Battery module anti-propagation

Preventing thermal runaway by limiting propagation to a single cell within a module.

Busbar

• Shielding from external flames and high temperature

• High electric insulation properties >10 kV

• Ultra-low thickness requirements

• Dry-film and spray-on solutions

• Designed for mass-scale applications

• Compatible will metals and plastics with minimal surface treatment

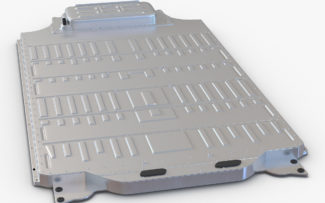

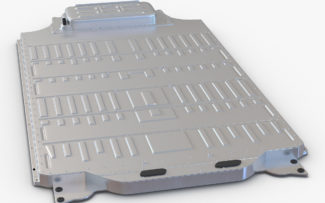

Cooling plate

• Blast-protection of the cooling plate

• Flexible and easy to cut in shape and apply solutions

• Ultra-low thickness and compatible with different adhesive types

• Mica-free solutions

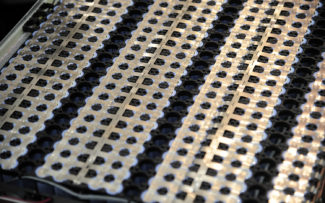

Cylindrical cell

• Thermal barrier solutions and rebound protection

• Cell-to-cell thermal insulation and protection

• Reducing chain reaction risk through rebound protection solutions

• All solutions are mica-free and can be made locally

• Tested and verified with live cells (1865 to 46xx)

External fire

• Superior shielding from external flames and high temperatures

• Ultra-low thickness requirements

• Dry-film and spray on solutions

• Designed for mass-scale applications

• Compatible will metals and plastics with minimal surface treatment

Fire retardant EV coating

Protect against explosion during extreme events such as battery related fires.

Hydrogen tank

• Shielding from external flames and high temperatures

• Ultra-low thickness requirements

• Designed for mass-scale applications

• Only minimal surface preparation

• Temperature resistance of up to 1300 °C

Material and product development

• Development of bespoke fire protection materials and products

• Development of anti-propagation materials and products

• Propagation fire protection

• Cell divider, insulation, and side wall protection

• Battery enclosure protection

Module / pack enclosure

• Protection of aluminium, steel, and plastic module and pack enclosures

• Protection against jet-flames and high velocity particles

• Temperature resistance up to 1300 °C

• Mica-free solution

• Flexible and easy to cut into shape

Pouch cell

• Complimentary portfolio of safety materials

• Thermal barrier solutions and cell dividers

• Cell-to-cell thermal insulation and protection

• Stop thermal runaway with thermal barrier materials

• All solutions are mica-free and can be made locally

• Tested and verified with live cells

Prismatic cell

• Thermal barrier solutions, cell divider and rebound protection

• Cell-to-cell thermal insulation and protection

• Reduce the risk of a chain reaction through rebound protection solutions

• Mica-free and can be made locally

• Tested and verified with live cells (93 Ah to 234 Ah)

Share your protection challenge

Do you need to protect equipment in an extreme operating environment? Find out how AIS can help.

Learn more