As offshore wind continues to grow in scale and complexity, so too does the demand for installation-ready, performance-driven subsea solutions. At the forefront of this is NjordGuard, a cable protection system (CPS) designed not just to protect, but to enable fast, efficient, and practical offshore deployment.

With a range of upgrades and component-level innovations, NjordGuard offers a truly sleek and integrated system tailored to meet the demands of offshore wind cable installation.

Designed for efficiency at offshore

NjordGuard has been engineered for ease of vessel-based assembly, a key factor in reducing offshore time, vessel costs, and operational risk. This efficiency is achieved without compromising on cable protection, ensuring safe, consistent performance even in harsh offshore environments.

The system’s modular design, streamlined components, and smart rigging interfaces allow for faster preparation, handling, and overboarding during cable lay operations. Helping offshore teams work more safely, more efficiently, and with greater confidence.

Key features of the updated system include:

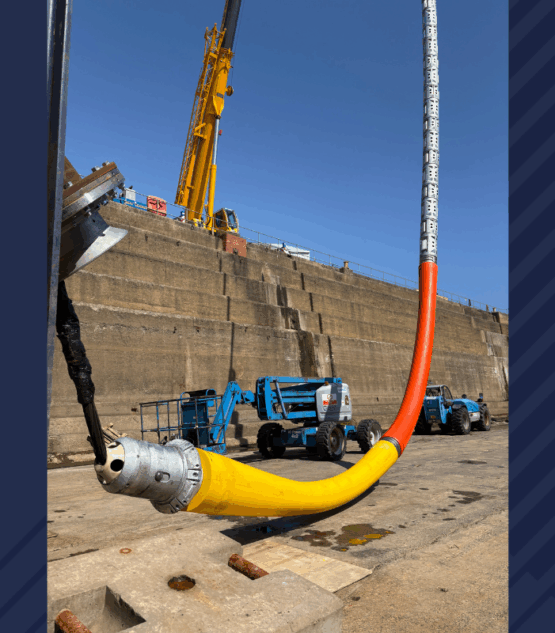

- New connector design - The system’s external stiffener and connector are delivered preassembled with a pull-in tool and rigging, reducing deck work and speeding up the cable pull-in process. Its sleek design ensures smooth entry into the monopile aperture with minimal resistance. The optimised part count and robust design ensure a reliable and trouble-free operational life.

- Super duplex interconnectors - A major advancement is the anode free super duplex interconnectors, which allows for rapid assembly without the need for rotational or symmetrical alignment. This simplifies offshore handling and significantly reduces installation time, while offering strong structural performance and corrosion resistance.

- Sleek ballast - The sleek ballast is available in preassembled lengths of up to 5 metres. Its simplified two-part design reduces the number of components that need to be handled during offshore operations. Its smooth outer profile ensures clean travel over cable lay vessel rollers and through the overboarding chute, supporting efficient and consistent installation. Its smooth inner profile minimises potential wear points on the cable, reducing the risk of cable failure due to internal abrasion.

- Streamlined polyurethane centre sections - The polyurethane profiles have been redesigned and paired with the super duplex interconnectors, reducing section thickness at connection points. This optimisation improves thermal performance without compromising strength, which is an important factor in maintaining the integrity of power cables under load. It also enhances abrasion resistance while maintaining the overall PU volume (and therefore cost too).

Built for fixed offshore wind turbine installation

NjordGuard is fully project-specific, designed to suit environmental and operational conditions of each offshore wind installation. It’s also adaptable, with a system also available for J-tube installations into bellmouths, providing the same levels of protection and efficiency across different entry methods. Additionally, a range of bore sizes are available to suit anything from a small fibre optic cable up to a large export cable, covering all known array cable dimensions.

NjordGuard is designed and qualified in accordance with API 17L, giving operators and developers confidence in its performance, durability, and compliance with industry standards.

From vessel deck to subsea floor, NjordGuard brings together the latest in cable protection engineering to deliver a sleek, high-performance system that reduces offshore complexity and supports fast, reliable wind turbine installation.

As offshore wind expands, solutions like NjordGuard ensure that installation speed and system reliability go hand in hand.

By Andy Smith, Head of Sales at CRP Subsea

Find out more about NjordGuard here or contact our expert team today to discuss your latest project.