CRP Subsea has recently been awarded multiple contracts from a prominent oil & gas flexible pipe manufacturer. The contracts involve providing buoyancy and bend protection solutions to a large gas field located in the Indian Ocean, off the coast of Western Australia.

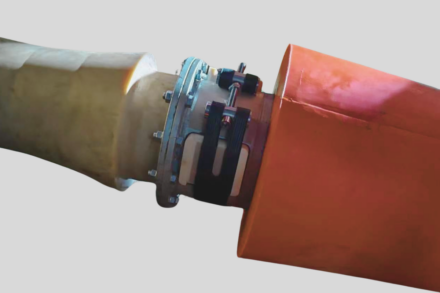

CRP Subsea will supply their innovative Distributed Buoyancy Modules (DBMs) utilising their market-leading compliant internal clamp technology. The DBMs will be installed on six flexible export risers, establishing and sustaining a subsea lazy wave configuration. The buoyancy clamp generates a controlled uniform circumferential clamping pressure round the riser, maximising the axial capacity of the clamp. Simultaneously, the compliant elements offer the necessary flexibility to accommodate expansions and contractions. Thereby eliminating the potential for pipeline damage while ensuring the modules maintain their position.

CRP Subsea's dynamic bend stiffeners are set to be deployed topside. They will protect the six flexible risers from both fatigue and over bending. This protection is specifically at the end termination points on a semisubmersible Floating Production Unit (FPU), located close to the field.

James Harrison, Key Account Manager at CRP Subsea states:

"We are thrilled to have been chosen for this significant project. Our customer's decision to select two of our solutions reaffirms their confidence in the superior performance and advantages offered by our market-leading products. We look forward to collaborating with them on this project and beyond, further solidifying our position as a trusted provider of buoyancy and bend protection."

Manufactured at CRP Subsea’s state-of-the-art-manufacturing facility in the North West of England. Project engineering works will start imminently, with final delivery in quarter 2 next year.

Product information

Distributed Buoyancy Modules (DBMs) are typically used between structures and a surface vessel or platform, providing uplift generated by a two-part buoyancy element and a clamp. CRP Subsea’s unique clamping solutions utilise a uniform circumferential clamping pressure to eliminate the risk of damage to the pipeline. The clamp also allows DBMs to be securely attached at any point along the length of a pipeline or cable and ensures the modules maintain their position.

A bend stiffener is a bend-limiting device used to protect flexible pipelines, umbilicals or cables. It does this in three ways; (1) They ensure the flexible pipe does not bend beyond the manufacturer's desired minimum bend radius (MBR) during the life of the project, in such a way as to optimise the fatigue performance of the flexible pipe. (2) They provide a suitable load path from the flexible pipe to the fixed structure. (3) Bend stiffeners reduce point loading at the termination point. We have an extensive track record in the supply of bend stiffeners, with zero failures.

Find out more about our Distributed Buoyancy Modules here

Find out more about our Bend Stiffeners here

Alternatively, contact our expert team today to discuss the buoyancy and bend protection requirements for your latest project.