CRP Subsea has secured a sizable contract from a prominent EPCI (Engineering, Procurement, Construction & Installation) to deliver cable protection services for an HVDC submarine cable project situated in the Arabian Gulf, offshore United Arab Emirates.

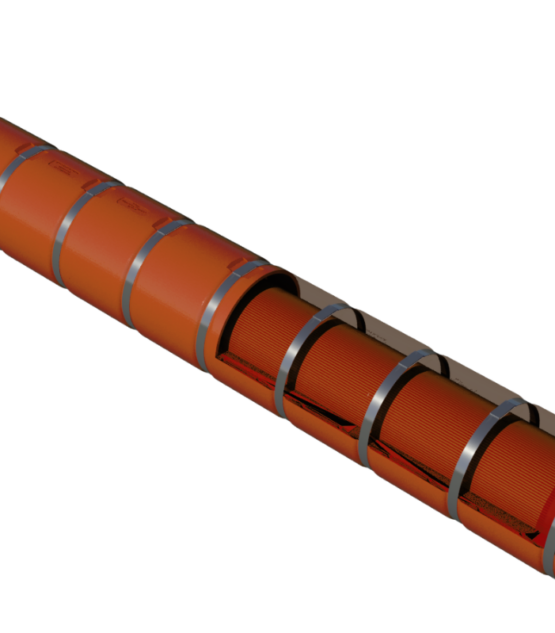

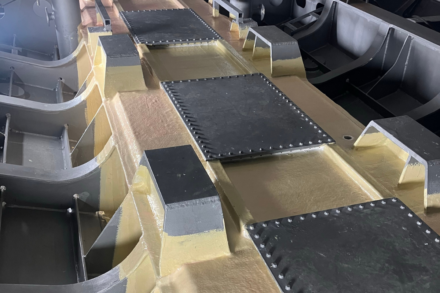

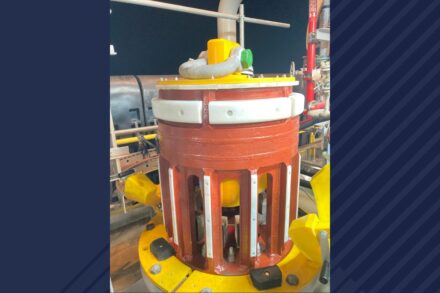

Over 6 kilometres of Uraduct® will be used at the cable crossings and platform approaches on the HVDC system. It will protect the cables from mechanical damage including crushing, abrasion and over-bending. We've used our engineering proficiency to provide three bespoke Uraduct® designs for this project. Two of which are for our bundled Uraduct® configuration, giving the customer the benefit of combining two or more cables into one piece of Uraduct®. Resulting in notable cost savings for the customer in terms of both product and installation expenses.

Ben Stubbens, Sales Team Manager at CRP Subsea states:

“We are thrilled that our market-leading Uraduct® has been chosen for this HVDC submarine cable project. This contract affirms our customers' confidence in our ability to deliver high quality cable protection. We are honoured to be part of such an innovative project that aims to improve energy efficiency as well as minimise environmental emissions.”

The engineering phase is set to commence imminently at our world-class production facility located in the North West of England. We have scheduled manufacturing activities to start this summer and anticipate final delivery by the end of the year.

The purpose of HVDC project is to deliver electricity from the onshore grid network to two offshore production facilities. The primary objective of this project is to reduce the use of the Gas Turbine Generators (GTGs). By doing so, the project seeks to increase the energy efficiency as well as reduce environmental emissions.

Product information

The demand for data and product transfer continues to grow on a global scale, requiring transfer networks to withstand increasingly harsh environments. This has created a need for highly advanced cable and flowline protection. Uraduct® was specifically designed and developed to fulfil this need. It offers comprehensive protection for a range of products, including fibre optic cables, power cables, umbilicals, flexible and rigid flowlines, hoses, and bundled products. In addition to safeguarding against abrasion and impact, Uraduct® can also add ballast to cables and flowlines. Its exceptional performance has established Uraduct® as an industry standard for cable and flowline protection.

If you have a requirement for Uraduct® cable protection, contact our expert team today to discuss your latest project.