Over the last four decades, the oil and gas industry has been a major focus of CRP Subsea's product offerings. During this time, we have gained valuable experience in providing buoyancy and cable protection solutions to our customers in this sector. This experience has enabled us to broaden our horizons and take on a new challenge: producing solutions for the emerging floating offshore wind farm market.

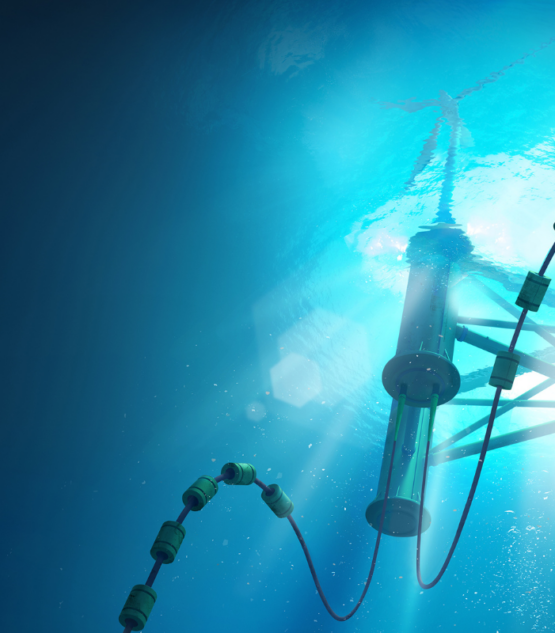

As renewable energy continues to gain momentum, offshore wind farms are becoming increasingly popular. Floating wind farms have the added advantage of being able to harness the strong winds found in deep waters. This makes them particularly appealing. However, designing and producing products for floating offshore wind farms present unique challenges. This is where our decades of experience in the oil and gas industry comes in. We have successfully transferred our knowledge, experience, material science, product design, and manufacturing techniques. We've transferred them from protecting subsea oil and gas infrastructure to protecting dynamic power cables. These are the cables that interconnect wind turbines and run between the substations and the shore.

Buoyancy

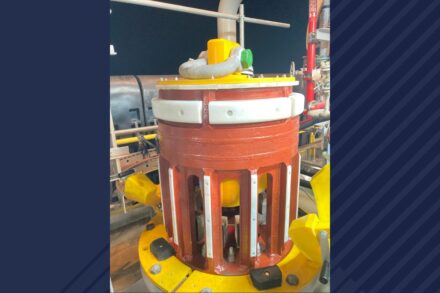

Our buoyancy modules have been widely used in the offshore oil and gas industry to hold pipelines in specific geometric configurations. Using advance clamping technology ensures the buoyancy module maintains its position without slippage. By utilising our extensive knowledge of buoyancy, we have developed effective and reliable solutions for floating offshore wind farms. An understanding of the complex ocean conditions has also contributed to the development of these solutions. Designing dynamic cable configurations for deeper water environments requires careful planning to ensure the longevity of the floating structures and the connecting power cables. A variety of cable configurations can be produced with the application of discrete buoyancy modules. These are placed at strategic intervals along the length of the cable. Selecting the correct buoyancy arrangement for the relevant conditions is critical. To make sure the cable loads and motions are managed and maintained within allowable limits.

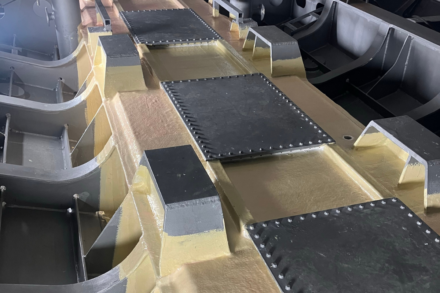

Cable protection

In addition, we have also applied our expertise in cable protection to the offshore wind farm industry. Protecting cables is crucial for maintaining the integrity of the wind farm's power supply. Our cable protection products have been proven to be effective in the harsh and challenging environments of the offshore oil and gas industry. Protecting cables from over bending and providing excellent abrasion and impact resistance in deep sea environments. We have adapted these products to meet the unique requirements of offshore wind farms. This ensures that cables are protected from damage caused by ocean currents, waves, and other environmental factors.

Our past experience has also given us an understanding of the importance of safety and reliability in offshore operations. We know that our customers rely on our products to perform flawlessly in challenging environments. We have made sure that our buoyancy and cable protection solutions for the floating wind industry meet the same exacting standards.

In conclusion, our decades of experience in providing buoyancy and cable protection solutions for the oil and gas industry have enabled us to apply our knowledge to the emerging floating offshore wind market. By utilising our expertise in these capabilities, we have developed reliable and effective solutions for this emerging market. By carefully considering the design and implementation of these systems, we can help floating offshore wind farms be a reliable and efficient source of renewable energy for years to come.

Click here to find out more about our floating offshore wind farm solutions. Alternatively, contact us today to discuss your requirements.