Working closely with Sharksilver, our marine team defined and recommended fendering solutions for both vessels that would meet all their specifications. This was within the demanding lead time of two-weeks to ensure their projects remained on track.

All our fendering is produced bespoke for each vessel that it must be fitted to, this ensures an accurate fit.

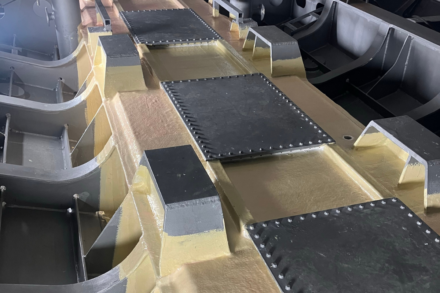

For one vessel, we recommended a sprayed PU fendering. Benefits of this solution include:

• Lightweight design which reduces fuel consumption and ensures the vessel reaches maximum speeds quickly

• Quick and easy to install

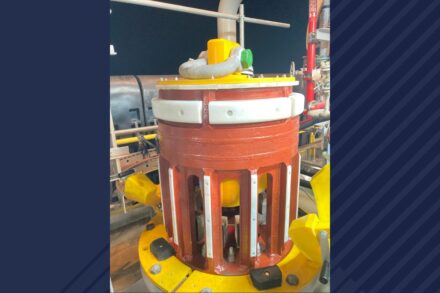

The second vessel required rubber fendering. If weight is not and an issue, rubber is a versatile cost effective alternative fendering to sprayed PU. We supplied a D type rubber fender profile, with the capacity to absorb high levels of energy through the presence of a relatively large hollow chamber.

The high energy absorption of both types of fendering will reduce the effect of any impact to the newly constructed vessels. We were delighted to be able support our customer and ensure they achieved their project timelines.