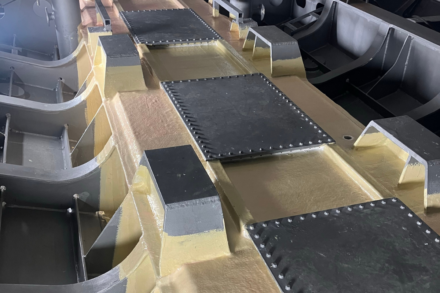

In the ever-evolving landscape of battery technology, the pursuit of safety and efficiency remains key. Innovation is the driving force behind advancements in any sector, and a solution in the world of battery protection is our ContraFlame® S1 materials. Our flagship products have a thin profile, sustainability features, and flexibility, offering a ground breaking solution for the industry.

Here are 5 key features of the ContraFlame® S1- Series:

- Thin Profile: The ContraFlame® S1- Series stand out for their impressively thin profile, measuring just 0.9 mm. This ensures S1 materials offer greater flexibility in design and application, making them an ideal choice for modern, compact battery configurations.

- Sustainable (non-mica-based): Sustainability is crucial in today's technology landscape. ContraFlame® S1 materials excel in this aspect by being free from mica, a material often associated with environmental concerns. This is without compromising performance.

- Highly Flexible: The flexibility of our ContraFlame® S1- Series opens up new possibilities in battery design and manufacturing. Their flexibility enables seamless integration into battery structures like enclosures or cooling plates, ensuring the overall design and functionality do not impede safety requirements.

- Suitable for use with battery cells up to 100 Ah: Catering to a wide range of applications for cylindrical, prismatic and pouch cells, ContraFlame® S1 materials are compatible with capacities of up to 100 Ah. This versatility makes them suitable for a diverse range of industries, from consumer electronics to electric vehicles.

- Compatible with adhesives or plastic overmoulding: ContraFlame® S1 materials offer flexibility not only in their physical properties but also in their application methods. Each one can be dry-fitted with or without an adhesive-backed layer, providing manufacturers with options to suit their specific production processes. Additionally, their compatibility with plastic-over-moulding is ideal for new and innovative manufacturing techniques.

Click here to find out more about this innovative solution, or contact our expert team today at [email protected].