CRP Subsea has successfully delivered a contract awarded by ECOnnect Energy, providing dynamic bend stiffeners for their IQuay™ jettyless LNG transfer system.

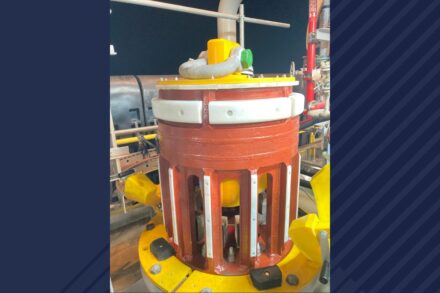

The innovative jettyless transfer system IQuay™ F-Class from ECOnnect Energy will be used to continuously transfer LNG gas from an offshore LNG production facility to a permanently moored floating storage unit (FSU). The IQuay™ solution replaces the need for a fixed jetty. CRP Subsea’s dynamic bend stiffeners will protect the flexible pipes to and from the IQuay™ system. They will provide additional stiffness and prevent the pipes from over bending at the termination points. As a result, this will allow for increased operational uptime even in inclement weather.

Ben Stubbens, Sales Team Manager at CRP Subsea states:

“This award is recognition of our technical expertise and unrivalled track record of providing bend stiffeners to the oil & gas industry for over 40 years. It’s a testament to our commitment to delivering reliable customised solutions that meet the unique needs of our customers. We are honoured to have the opportunity to work with such an innovative forward-thinking company and look forward to building a strong and long-lasting relationship.”

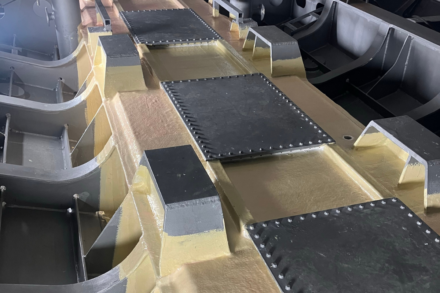

Produced at CRP Subsea’s state-of-the-art manufacturing facility in the North of England, the bend stiffeners have now been delivered. They will be installed when the IQuay™ F-Class is deployed later this year.

Product information

The IQuay™ leverages traditional marine infrastructure and existing LNG transfer operations, as it is optimised to be scalable as well as compatible with a wide range of Floating Storage Units (FSUs) and Floating Storage Regasification Units (FSRUs). The jettyless scope accelerates consumer access to natural gas in a cost effective and agile manner.

A bend stiffener is a bend-limiting device used to protect flexible pipelines, umbilicals or cables. It does this in three ways; (1) They ensure the flexible pipe does not bend beyond the manufacturer's desired minimum bend radius (MBR) during the life of the project, in such a way as to optimise the fatigue performance of the flexible pipe. (2) They provide a suitable load path from the flexible pipe to the fixed structure. (3) Finally, bend stiffeners reduce point loading at the termination point. CRP Subsea have an extensive track record in the supply of bend stiffeners, with zero failures.

If you have a requirement for cable protection, contact our expert team today to discuss your latest project.