CRP Subsea has been awarded several contracts from a prominent Chinese provider of land and subsea cable solutions. These contracts involve the supply of comprehensive packages comprising buoyancy, clamping, and cable protection solutions for oil fields situated in the South China Sea.

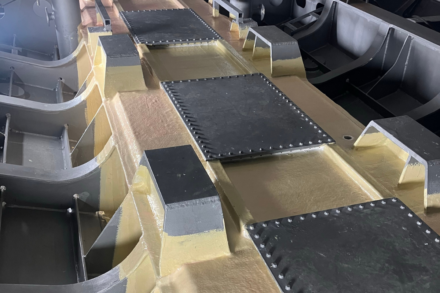

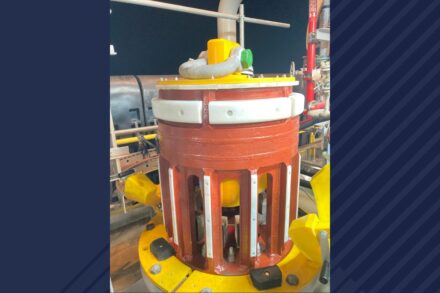

CRP Subsea will supply its distributed buoyancy and ballast modules, utilising its range of compliant, industry-leading internal clamp technology. The clamps feature a uniform circumferential clamping pressure, which eliminate any risks of damaging the dynamic cables and ensure that the modules maintain their position. Additionally, an engineered high-capacity compliant tether and hold-back clamps, will be installed on the dynamic cable and anchored to the seabed to keep them in the desired position. Dynamic bend stiffeners will also be provided to protect the cables from fatigue and over-bending at the termination points.

Matt Burrows, Sales Manager at CRP Subsea states:

“These recent awards have not only strengthened our relationship with a key customer but have also helped expand our presence in East Asia. The comprehensive package of goods awarded showcase our versatility and engineering expertise as a market-leading provider of subsea cable protection solutions to the oil & gas and renewables markets. We are delighted to have been chosen for these projects and look forward to continuing our successful relationship with the customer.”

Project engineering works will begin immediately, with completion and delivery expected in the second half of 2023.

Product information

Distributed Buoyancy Modules (DBMs) are typically used between structures and a surface vessel or platform, providing uplift generated by a two-part buoyancy element and a clamp. CRP Subsea’s unique clamping solutions allow DBMs to be securely attached at any point along the length of a rigid or flexible pipeline or cable. From standardised clamps, where the technical demands are more benign, to the highest performing clamps the right solution can be provided.

Tether clamps keep a dynamic flexible pipe, umbilical or cable in a desired position. They are often used when flexibles are in close proximity and help avoid clashing. The tether clamp is installed on the flexible and is then connected to a seabed anchor or gravity base using a tether system.

Bend stiffeners are used to provide additional local stiffness to the umbilical or flowline, the conical shape provides gradual increases in the overall stiffness of the umbilical or flowline, in order to prevent over bending at the termination point.

To discuss the requirements of your next project, contact our expert team today.