Barrel buoys (also known as admiralty buoys) have traditionally been made in steel. This can be problematic for operators due to:

• Need for regular maintenance checks (at least once per year) to check for rust. When there are signs of rust, it needs to be removed and the buoy repainted. If the rust is not removed and repaired, there is a significant risk that the buoy will erode enabling water to seep inside, which ultimately will result in the buoy sinking

• Marine growth that needs to be removed

• Depending on the size of the buoy, they can be incredibly heavy to lift out of the water and may need specialist lifting equipment to lift safely

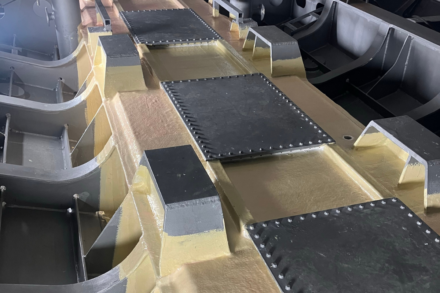

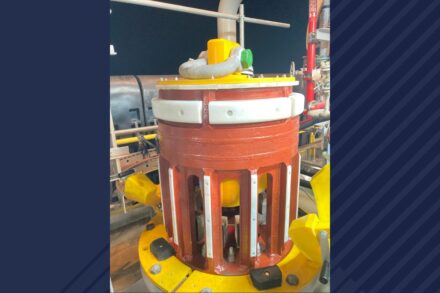

By recommending our lightweight barrel buoys produced using our foam-filled technology, a port in southern England will be able to avoid these issues. This reduction in maintenance allows our customer to achieve long term cost and maintenance time savings. Using foam-filled technology minimises maintenance and provides self-fendering properties – if the buoys are hit when operational, the damage will be non-existent as the vessel will bounce off. If the collision had been between a vessel and a steel buoy, there could have be significant damage.

Depending on the operational needs of your port, our barrel buoys can be supplied in different colours and can be produced with features including:

• Radar reflector

• Lights

• Different steel-work configuration

If you would like to discuss your port and the challenges you have, talk to our marine team to find out more about our full range of products and our solutions.