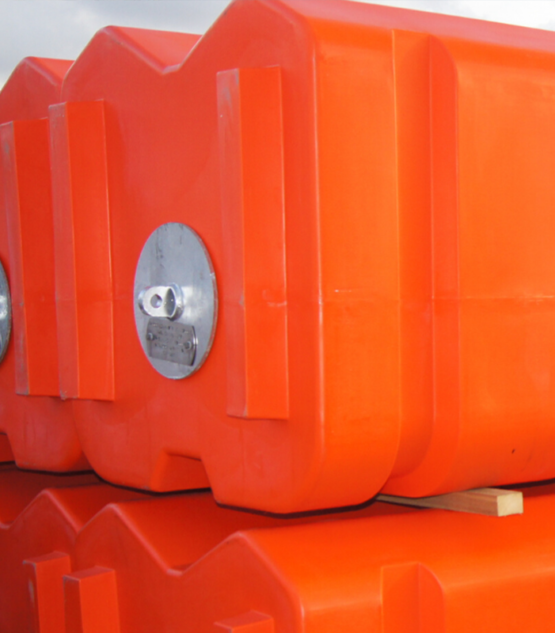

At AIS, we ensure the correct configuration of pipe laying floats for each project, resulting in added effectiveness and speed of pipe deployment. Speed can be a critical factor for our customers who may be working against challenging weather conditions or need to meet project timelines.

Pipe Laying Floats are primarily used as temporary buoyancy modules. They are strapped to a pipeline to reduce tension and weight during the installation process for surface or deepwater pipeline installation applications.

Our floats are designed to fit specific requirements with the following configurations:

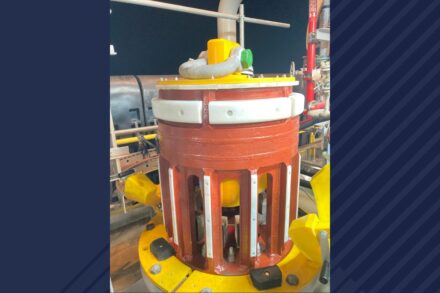

• Single piece unit configured with either an open through-hole or with a through chain and shackles to assist with handling operations

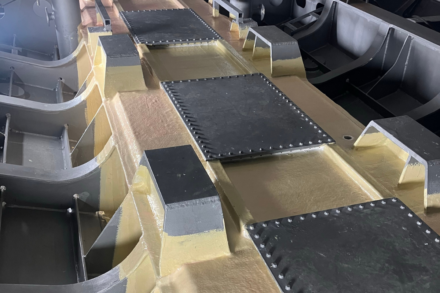

• Modular float configuration consisting of multiple individual units secured together with a central through pipe complete with pad eyes each end.

Both configurations have strap/band recess built into the buoyancy units to locate bands used to secure the buoys to the pipeline. A range of depth ratings is available from the surface to 3000MSW.