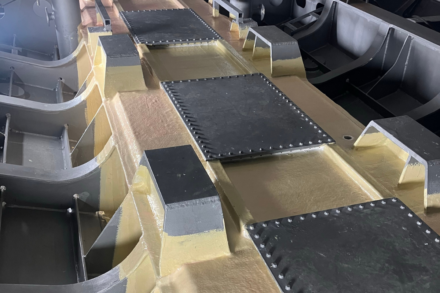

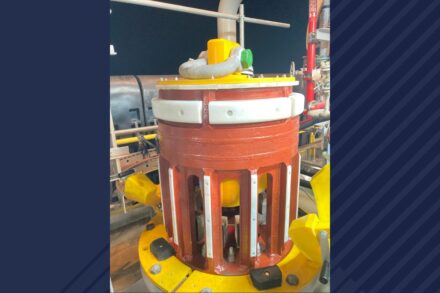

Our removable passive fire protection, acoustic and insulation jackets, are manufactured globally in our own manufacturing facilities.

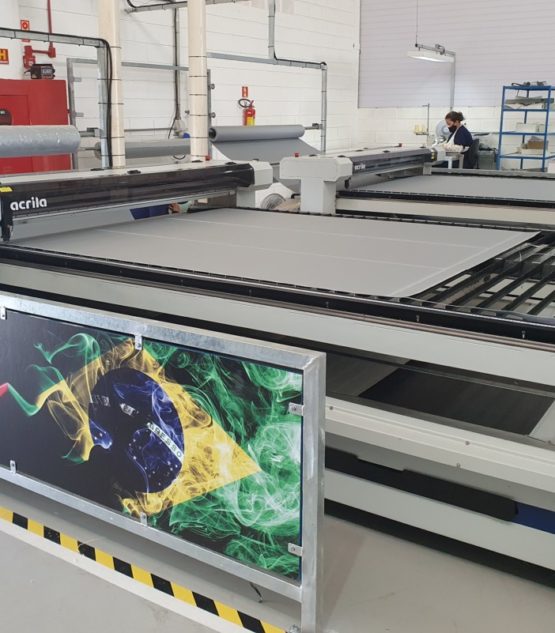

We are committed to meeting our customers’ unique and evolving needs by continuously improving our manufacturing capabilities and capacity. The recent addition of a further laser cutting table in our Brazil facility has significantly increased our production capability. In addition, thanks to the improved cutting method, we have seen a 25% decrease in waste to landfill.

Our investment in this advanced laser cutter is another example of our commitment to increasing production capacity while reducing waste.

For more information about our ContraFlex® range of products visit our ContraFlex® product page