CRP Subsea has been awarded substantial contracts by a major oil & gas OEM. We will supply two market-leading solutions for a deepwater gas field in the South China Sea, offshore China.

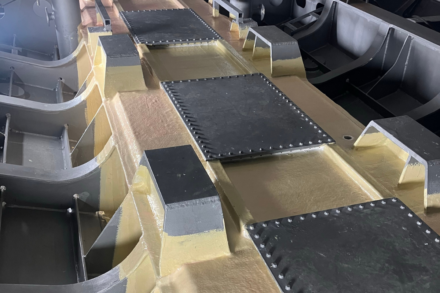

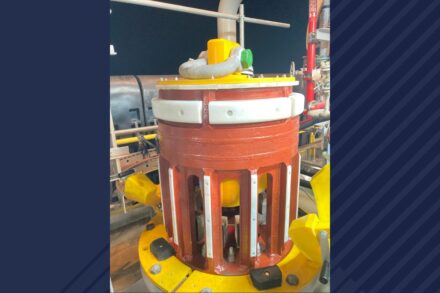

Our innovative integral buoyancy modules will be attached to dynamic and SSIV (Subsea Isolation Valve) umbilicals to provide the required lazy wave configuration. Using an integral compliant clamping technology ensures a uniform clamping pressure, and eliminates the risk of damage to the umbilical. A bend stiffener will be supplied to provide additional local stiffness to the umbilical, protecting it from overbending at the termination point.

Ben Stubbens, Sales Team Manager at CRP Subsea states:

“After successful previous supply, this award is a testament to our commitment to delivering high-quality and reliable solutions that meet the evolving needs of our key customer. We are thrilled to have been chosen to supply two of our innovative solutions for this project. We look forward to developing our long-standing relationship built on trust and mutual success.”

Engineering works are due to commence at our world-class production facility in the Northwest of England this year. Completion and deployment will be in mid-2023.

Product information

Integral buoyancy modules clamp directly to subsea pipelines providing buoyancy at specific locations. They combine the functions of the traditional clamp and buoyancy elements into one unit, so there is no need for a separate internal clamp assembly. As a result, they have fewer component parts enabling faster and more cost-effective installation. Integral buoyancy modules offer improved handling using an innovative lightweight installation tool, consequently providing enhanced safety.

A bend stiffener is a bend-limiting device used to protect flexible pipelines, umbilicals or cables. It does this in three ways; (1) They ensure the flexible pipe does not bend beyond the manufacturer's desired minimum bend radius (MBR) during the life of the project, in such a way as to optimise the fatigue performance of the flexible pipe. (2) They provide a suitable load path from the flexible pipe to the fixed structure. (3) Bend stiffeners reduce point loading at the termination point. We have an extensive track record in the supply of bend stiffeners, with zero failures.

If you have a requirement for buoyancy or cable protection, contact our expert team today to discuss your latest project.