CRP Subsea has recently secured a substantial contract with a leading energy technology company. The contract involves the supply of distributed buoyancy modules (DBMs) to a deepwater oil field project situated in the pre-salt Santos Basin, offshore Brazil.

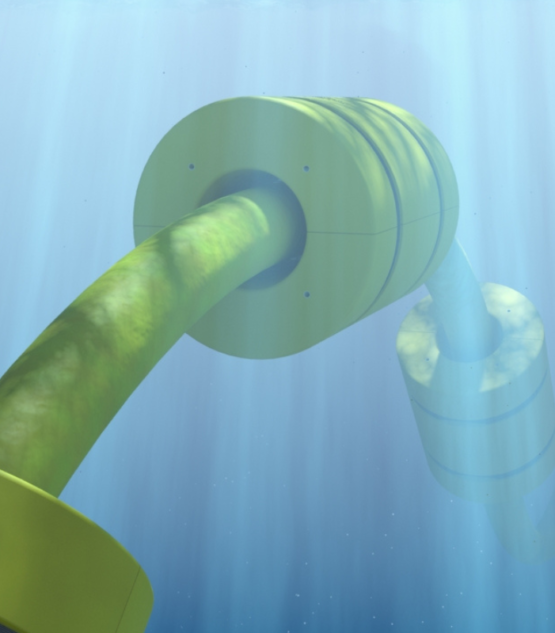

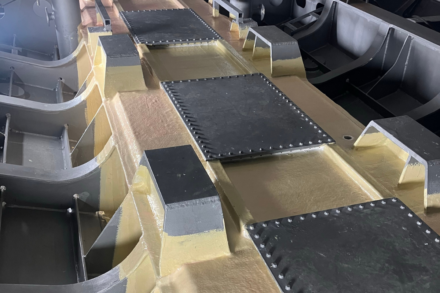

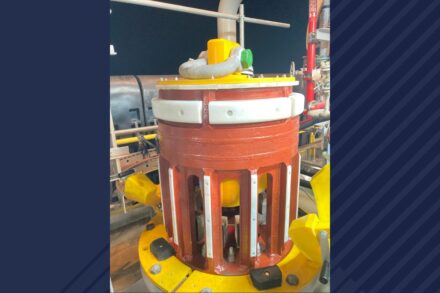

CRP Subsea’s DBMs will be utilised on a flexible production riser transporting oil from the subsea facility to the floating, production, storage and offloading (FPSO) vessel above. Specifically engineered, the DBMs will establish a dynamic subsea lazy-wave configuration to mitigate the top tension on the FPSO. They feature a high-capacity compliant internal clamp, intricately designed to ensure controlled and uniform circumferential clamping pressure around the riser. This not only maintains the position of the DBM but also eliminates the risk of pipeline damage, contributing to the prolonged lifespan of the field.

James Harrison, Key Account Manager at CRP Subsea states:

"We are thrilled to have been selected by a key flexibles customer for this project. It is great that our market-leading internal clamp technology is consistently chosen as the preferred solution. Recognised for minimising installation risks and ensuring the reliable operation of deepwater flexible risers, our technology sets the standard. We look forward to this and future collaborations with our valued customer."

Manufactured at CRP Subsea’s state-of-the-art-manufacturing facility in the North West of England. Project engineering works are set to commence imminently, with delivery scheduled for June this year.

Product information

Distributed Buoyancy Modules (DBMs) are typically used between structures and a surface vessel or platform. They provide uplift generated by a two-part buoyancy element and a clamp. CRP Subsea’s unique clamping solutions allows DBMs to be securely attached at any point along the length of a rigid or flexible pipeline or cable and ensures the modules maintain their position.

Find out more about our Distributed Buoyancy Modules here.