Global engineering companies work with their customers to provide equipment to enhance the efficiency and effectiveness of their plant operations. The equipment supplied might reduce the amount of energy used in the application or it might give the operator more control over the flow of energy.

Including the supply of insulation jackets with the equipment, can enhance the outcome for the customer. Not only that, but it can provide additional benefits such as noise reduction. This helps to ensure the noise within their plant remains below local health and safety limits.

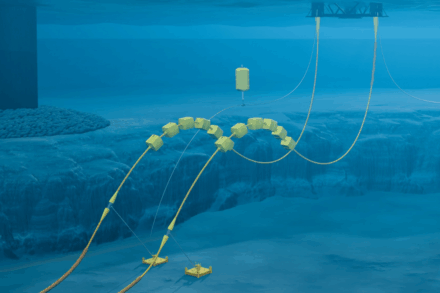

Traditionally, equipment such as piping packages were either not insulated or insulated using mineral fibre or cladding. Insulation for flanges, valves and steam traps, was usually a box method that can be costly, time consuming to install and difficult to remove for maintenance purposes.

Benefits of insulation jackets

ContraFlex® jackets provide a fast-fit, cost effective alternative solution to traditional methods. Supplied ready to install, there is no requirement for extra tooling. The jackets are designed to be easy to remove for inspection or maintenance programs. We can include inspection hatches to enable equipment to be monitored whilst insitu.

Used extensively for thermal insulation by steam distribution companies these jackets provide a cost-effective solution to which significantly reduces energy loss on both new build and as a retrofit solution. Fitting insulation jackets to equipment can reduce the risk of injury to operators and improve the working environment, by reducing external temperatures and reducing noise levels.

Why ContraFlex® insulation jackets?

We have global manufacturing capability at our facilities in Brazil, Dubai, Kazakhstan, Korea and UK. This means our jackets are easily sourced by local and multinational OEMs – with consistency in supply guaranteed for your customers’. Our global manufacturing facilities can supply both standard and bespoke thermal insulation solutions for a variety of applications.

We’re able to flex our production capability to ensure you have the jackets when needed. To make the process even easier for you, we can design bespoke jackets that can be held in stock for your standard equipment and agree global pricing structures if that is what you require. Our jackets are available in an infinite number of shapes and sizes to suit a broad range of thermal insulation applications and can be tailored to fit almost any equipment easily.

Service and support

We can provide training on how to install and fit the jackets to ensure that your installers can fit when installing your equipment. Our team are also available to provide lunch and learn sessions to your sales team to explain the added benefits of insulating equipment. We have a range of information that you can share with your customers.

Our local teams are available to provide on-site service and support, which can include installation and removable. If your customer is unsure of the benefit of fitting insulation jackets, we can conduct a site survey using FLIR thermal imaging cameras which can be used to analyse heat losses on non-insulated items and provide calculations for return on investment, (ROI).