Floating offshore wind is one of the most exciting areas of the energy transition. By unlocking deeper waters and stronger wind resources, it expands the available seabed far beyond what fixed-bottom projects can reach.

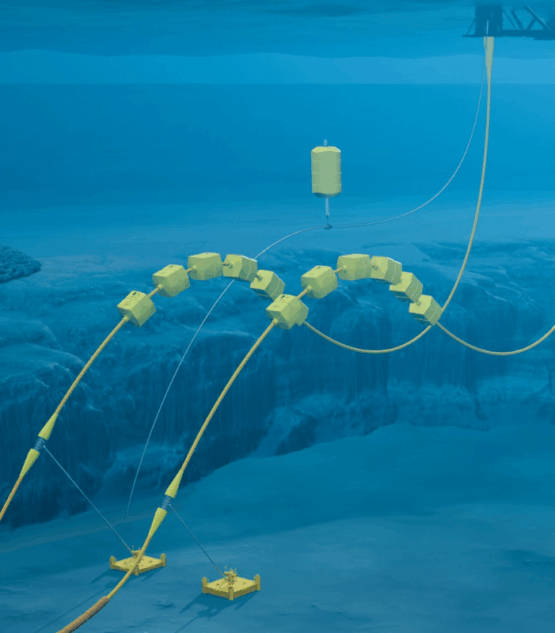

Beneath the waves lies a quieter revolution. Subsea ancillaries, the unsung hardware that connects, protects, and stabilises dynamic cables and mooring lines, play a decisive role in project success. Without them, turbines can’t reliably deliver power back to shore.

What are subsea ancillaries?

The term covers a family of components designed to protect cables, manage loads, and enable safe long-term operation in harsh marine environments:

- Buoyancy modules (NjordFloat) - add uplift to subsea lines to control configuration and tension.

- Bend stiffeners - prevent over-bending of dynamic cables at turbine or floater interfaces.

- Cable protection (Uraduct®) - shield subsea power cables from abrasion, fishing gear, and seabed movement.

- VIV strakes - suppress vortex-induced vibrations on dynamic cables, reducing fatigue damage.

- Tether systems - secure floating platforms to seabed anchors while also guiding or supporting dynamic cables to control movement and reduce fatigue.

- Ballast modules - add weight to stabilise subsea lines or maintain desired seabed contact.

- Cable crossing solutions - engineered structures that safely route export and inter-array cables across pipelines or telecom cables.

- Installation buoyancy modules - provide temporary flotation to support and position cables or moorings during installation.

- Mooring buoyancy modules - manage line profiles, reduce drag, and protect against fatigue.

- Cable protection systems (CPS) - safeguarding cable management into fixed bottom applications, such as offshore substations (OSS).

In floating offshore wind, these ancillaries primarily support inter-array and export power cables, which are the critical electrical links between turbines and shore. They also help stabilise mooring and tether systems, manage fatigue, and maintain proper line profiles for safe and efficient operation.

Ancillaries are critical, but why…

- Mitigating single-point failures

Subsea cables are one of the top failure points in offshore wind. Ancillaries like bend stiffeners and cable protection systems reduce the risk of costly outages. - Managing fatigue and dynamic loads

Floating wind turbines move constantly. Without properly designed ancillaries, dynamic cables and mooring tethers would degrade far faster than predicted. - Reducing installation and maintenance costs

Smart protection systems simplify handling, reduce vessel time, and lower the need for ROV interventions, saving millions over a project’s lifetime. - Enabling deeper, harsher sites

As the industry pushes into deeper waters and more energetic environments, reliable subsea ancillaries make these projects technically and economically feasible.

Opportunities for suppliers and developers

- Innovation in fatigue-resistant design: Smarter materials and geometries extend asset lifetimes.

- Standardisation: Interoperable ancillaries reduce engineering time and simplify procurement.

- Lifecycle services: Inspection, repair, and replacement strategies will grow as fleets mature.

- Digital monitoring: Embedding sensors into bend stiffeners, buoyancy modules, and connectors provides operators with predictive maintenance data.

Partnering with the right supplier

As the floating offshore wind sector grows, the choice of subsea ancillary supplier directly impacts project reliability and cost. With decades of offshore experience, CRP Subsea, an AIS company, is uniquely positioned to deliver proven solutions, including bend stiffeners, Uraduct® cable protection systems, tether systems and connectors, mooring and installation buoyancy modules, VIV strakes, ballast modules, and cable crossing solutions.

Our subsea ancillaries are engineered for durability in harsh marine environments, helping developers and operators reduce risk, manage fatigue, and lower lifecycle costs. By partnering with us you gain not just high-quality products, but also a trusted partner supporting your floating wind projects from design through installation and long-term operation.

Ensure the reliability of your floating offshore wind projects.

Contact us today to learn how our subsea ancillary solutions can support your next project.

By Ben Wait, Business Development Manager at CRP Subsea