Did you know that AIS has its own dedicated team of patternmakers?

Many of the materials we use are cast directly onto our customers’ structures using steel mould tooling. However, when the geometry becomes too complex for traditional fabricated tools, a more engineered solution is required. This is where our skilled patternmakers step in.

Pattern making (sometimes referred to as mould making) involves the creation of precision mould tools with exceptional skill and attention to detail. These tools are often highly intricate, demanding tight tolerances, superior surface finishes, and, at times, custom modifications. Our team combines traditional craftsmanship with state-of-the-art machining techniques, ensuring every mould meets exacting specifications with outstanding accuracy and repeatability.

Having our own in-house pattern making department means we can respond quickly and provide innovative solutions, no matter how complex or technically challenging the project. This allows us to maintain full control over the process, guarantee consistent quality, and deliver results on time for our customers.

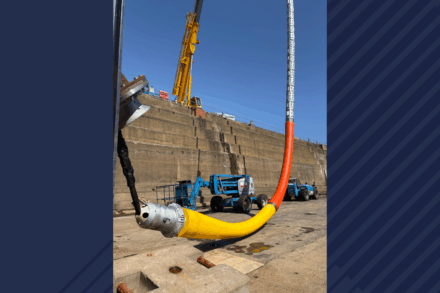

Below is an example of the custom tools we’ve created, and the finished parts produced from them.

We are proud of the expertise and dedication our patternmakers bring to every project, helping AIS set the standard for excellence in our industry.