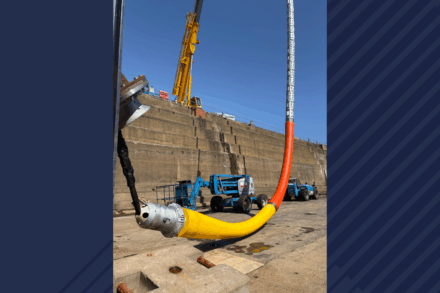

Water intake risers (WIRs) used by FPSO and FLNG units supply the required volume and flow of cold water to cool the topside processes.

Traditional solutions made from rubber and steel have several limitations. Not only are these solutions stiff and come with diameter restrictions, but using rubber limits pumping depth and the weight is not cost effective. However, AIS Bardot WIRs are made from high-density polyethylene, qualified for use offshore by most major oil companies. This material ensures our solution is low in weight, saving our customers crucial operating costs. In addition, our WIRs pump water from as deep as 800m and withstand the most challenging operational conditions.

Our deep water intake risers save maintenance costs and time, as only routine inspections are necessary. Installed via a customised procedure, we tailor each solution to the unique needs of a project. So, no matter what the FPSO or FLNG configuration, our team adapts the assembly of the equipment, and our engineers can provide extra training to smooth the process.

AIS Bardot WIRs deliver an industry-best performance for cooling essential equipment and preventing overheating on your FPSO or FLNG. Talk to our team today to find out how our innovative solution can save operating costs for your project. Or follow us on LinkedIn for more news about our range of innovative products.