Climatic and life testing

Our expertise in climatic and life testing of batteries enables our customers to identify potential failure modes and ensure batteries can operate effectively in real-world conditions.

With advanced cyclers, CAN-enabled monitoring, and controlled environmental chambers, we deliver accurate data to help customers evaluate performance, durability and safety. Our expert team also offers post-test advice to improve battery design and performance.

Why AIS?

Expertise in battery safety

Our advanced testing facilities and cutting-edge equipment allow us to simulate a wide range of climatic conditions. These include extreme temperatures, humidity, and vibration from our advanced test facility, Europe's largest battery testing and material development centre.

Extreme condition simulation

Our state-of-the-art facility allows us to subject batteries to a range of conditions and environmental factors to evaluate battery performance under extreme conditions. These tests ensure batteries can endure life-long usage even under extreme conditions.

Market expertise

Having conducted 1000's of tests in-house, our understanding of life testing, cycling and operational stress tests is market-leading. We assess how batteries maintain their performance, capacity, and their overall safety over prolonged use.

Post test analysis

Customers use our analysis service to evaluate test results and identify potential failure modes. To enhance the safety of your batteries, our expert team will provide advice on battery design to help improve reliability in real-world applications.

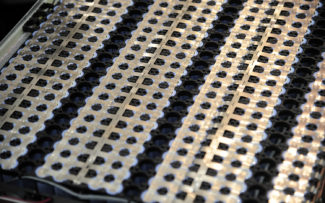

Cell Cycling

- High-current cycling across hundreds of independent channels for advanced performance and endurance testing.

- Precision control of current, voltage, and temperature to characterise cell behaviour, degradation, and aging across complex drive cycles or custom loading profiles.

- Comprehensive data logging with multi-channel thermal, analogue, and digital monitoring for detailed analysis.

- Controlled environments with temperature cycling from -40 °C to +80 °C, enabling reliable testing across a wide range of operating conditions.

Module Cycling

- High-current, high-voltage cycling channels suitable for a variety of module configurations and applications.

- Accurate control of all key test parameters, ensuring consistent and repeatable results.

- Comprehensive monitoring of temperature, balancing performance, and system-level signals throughout each test.

- Environmental chambers capable of replicating extreme temperature conditions from -40 °C to +80 °C, simulating real-world operating environments.

- Parallel testing capacity, allowing multiple programs to run simultaneously for maximum efficiency.

Pack Cycling

- High-current (up to 3,200 A) and high-voltage (up to 1,000 V) cycling channels capable of delivering up to 2 MW of power, enabling realistic simulation of demanding duty cycles.

- CAN-enabled data acquisition for real-time communication, performance feedback, and fault detection.

- Comprehensive monitoring across all system parameters, including temperature sensing, analogue diagnostics, and digital system signals.

- Large environmental chambers and chillers that achieve temperature transitions between-40 °C and +80 °C in under 30 minutes, allowing rapid test cycling.

Share your challenge

Do you require climatic and life testing services from an expert team? Find out how AIS can help.

Get in touch