ContraTherm® C55 has been meeting these challenges head-on for over two decades. With a proven, fault-free service history across major subsea projects worldwide, it has become a trusted solution for delivering long-term pipeline flow assurance.

Proven performance

ContraTherm® C55 offers reliable performance which has continually delivered in harsh environments, protecting against temperatures of up to 150°C and hydrostatic pressure resistance at water depths of up to 3000 m.

A certification-backed solution, ContraTherm® C55 meets the following operator and industry standards:

- Total GS EN COR 226 compliant

- ExxonMobil GP650801 compliant

- ISO 12736 compliant for wet thermal insulation systems

Reduced installation complexity

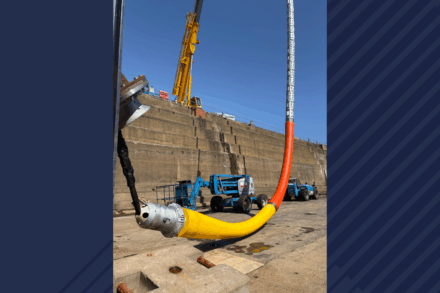

Traditional subsea insulation systems can require specialist mould tooling, pumping equipment, and extended installation timelines, adding cost and complexity to projects. ContraTherm® C55 offers a more efficient alternative.

As a pack-in-place solution, C55 can be hand-applied directly to equipment at customer sites without the need for complex or bespoke tooling. This allows AIS application teams to work efficiently, even on structures with challenging geometries or demanding schedules, helping projects stay on track without compromising quality.

A trusted solution

With more than two decades of proven service, ContraTherm® C55 continues to be selected by global operators as a dependable solution for subsea insulation. Its long-standing track record, ease of application, and certified performance make it the ideal choice for projects operating in unforgiving environments.

Watch the below video, where Sales Manager Vicky James explains why ContraTherm® C55 has maintained such a strong track record with global operators, and why it continues to be chosen time and time again.