CRP Subsea has secured a sizable contract from a major engineering, procurement, construction and installation (EPCI) company. The contract involves the provision of modular buoyancy modules for a deepwater oil field development, located in the Santos Basin, off the coast of Brazil.

The modular buoyancy modules will be utilised onboard an installation vessel, providing essential weight adjustments for subsea structures during installation, in water depths in excess of 2,000 metres. CRP Subsea will leverage its advanced engineering expertise to deliver six distinct variants, tailored to meet the customer's unique specification. This includes the provision of tandem assemblies with uplifts up to 46 metric tonnes, ensuring utmost adaptability and efficiency in even the most demanding underwater environments.

Gavin Moore, Sales Manager, states:

“This project is the latest addition to our growing number of recent awards for the supply of modular buoyancy globally. It reaffirms our extensive track record and proven solutions for subsea buoyancy. These awards reflect the continued trust and confidence of our valued customers, with whom we have developed longstanding relationships over the years. Such recognition only serves to strengthen these important partnerships, paving the way for future collaborations.”

CRP Subsea will design and manufacture the modular buoys at its production facility in the North West of England. Project engineering works are set to commence imminently. Delivery is expected later this year for offshore use in early 2025.

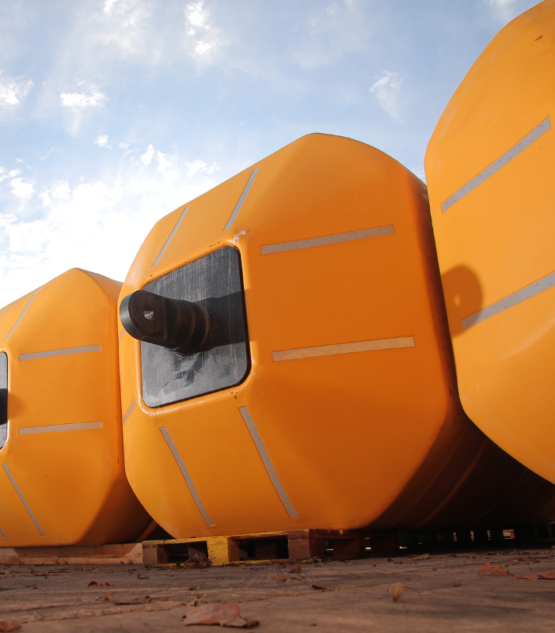

Product information

Modular Buoyancy serves a variety of short and long-term applications, from providing weight compensation during the installation of diverse subsea equipment. It offers permanent buoyancy for mooring chains, jacket leg platforms, and flowline buckling mitigation systems.

Featuring a modular design, these buoyancy systems can be tailored to meet specific water depth and upthrust requirements. Each module is built with an engineered structural core, ensuring maintenance-free performance over its entire design life. Additionally, the interlocking male and female spigots effectively eliminate the risk of module rotation during usage.

If you have a requirement for modular buoyancy, contact our expert team today to discuss your latest project.