CRP Subsea has been awarded a substantial contract from a prominent EPCI (Engineering, Procurement, Construction & Installation) company. The contract involves the supply of distributed buoyancy modules (DBMs) to a natural gas development off the Eastern Mediterranean coast.

The DBMs will be deployed on dynamic umbilical and MEG (mono-ethylene glycol) risers, which connect to a floating production, storage, and offloading (FPSO) unit positioned above operating at depths of approximately 1,800 metres. The DBMs are engineered to ensure the risers can withstand the challenging offshore environment, including wave forces, currents, and the motions of the FPSO. This is achieved using a high-capacity compliant internal clamp, that applies a controlled, uniform circumferential pressure around the riser. The clamps ensure that the DBMs remain securely in place maintaining a lazy-wave configuration.

Matt Burrows, Sales Manager, comments:

"Securing this contract is a reflection of the trust and collaboration we have built with our customer. It reinforces our commitment to delivering customised, high-quality solutions to our key customers. We look forward to strengthening this partnership further through this project and beyond.”

Production of the distributed buoyancy modules will take place at our site in Skelmersdale. The project engineering works are due to start shortly, with delivery scheduled for Q1 2026.

Product information

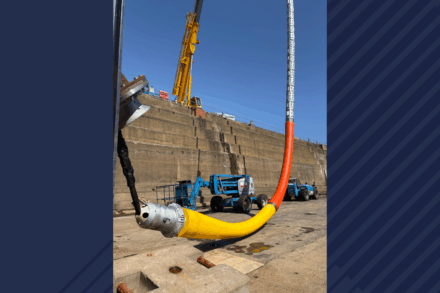

Distributed buoyancy modules (DBMs) are typically used between structures and a surface vessel or platform. They provide uplift generated by a two-part buoyancy element and a clamp. Our unique clamping solutions allows DBMs to be securely attached at any point along the length of a rigid or flexible pipeline or cable and ensures the modules maintain their position.

Find out more about our distributed buoyancy modules here.